DRR S/Pro

| Larry, what size is that sbc? Any specs to share? |

| | |

DRR Pro

| Markemark, The Simply Square mill is a 383 4.030 x 3.75. High compression, [Mahle tall dome piston] skinny low tension rings, Brodix Dragon Slayer heads, Brodix manifold, APD Methanol fuel system, [it will have an APD 2" spacer] Custom Cams per this combination, OE Chevy block, 1 3/4 x 1 7/8 x 3.5 header, Powerglide, 6200 converter, 1.80 low, 5.40 rear gear. Expected operating range: 6,000 - 7,400 RPM. The truck will weigh around 2850 with the driver and should run 6.30 ET.

Larry Woodfin

|

| | | Posts: 2088 | Location: Longview TX | Registered: March 12, 2004 |    IP

IP

|

|

DRR Pro

| Curtis, the "Super 10," was sold to Troy Morgan and then another racer. To my knowledge, he is still racing it.

Larry Woodfin

|

| | | Posts: 2088 | Location: Longview TX | Registered: March 12, 2004 |    IP

IP

|

|

DRR S/Pro

| quote: The Simply Square mill is a 383 4.030 x 3.75. High compression, [Mahle tall dome piston] skinny low tension rings, Brodix Dragon Slayer heads, Brodix manifold, APD Methanol fuel system, [it will have an APD 2" spacer] Custom Cams per this combination, OE Chevy block, 1 3/4 x 1 7/8 x 3.5 header, Powerglide, 6200 converter, 1.80 low, 5.40 rear gear. Expected operating range: 6,000 - 7,400 RPM. The truck will weigh around 2850 with the driver and should run 6.30 ET.

I would bet excessive wheels up (no bars) having 5.43 / 1.80 SLR. That cu.in. with DS heads, 13.5+ on methanol probably is 675+ in a good build. 5.14 better or 5.29 less better more appropriate racing 1/8. 5.14 will get you over 7k finish line and more mph imho. |

| | |

DRR S/Pro

| ^^^^^^^^^ Did you install needle or bushed roller lifters? |

| | |

DRR Pro

| Markemark, I used Crower needle rollers. Springs are Isky 270 seat - 685 open.

Larry Woodfin

|

| | | Posts: 2088 | Location: Longview TX | Registered: March 12, 2004 |    IP

IP

|

|

DRR Pro

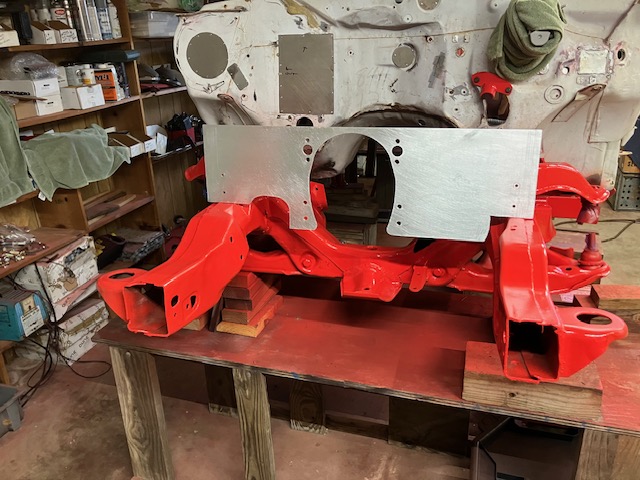

| Tomorrow, the firewall will be yellow

Larry Woodfin

|

| | | Posts: 2088 | Location: Longview TX | Registered: March 12, 2004 |    IP

IP

|

|

DRR S/Pro

| quote: Tomorrow, the firewall will be yellow

Did you run out of red spray paint? |

| | |

DRR Pro

| Markemark, all the framework and roll bars will be red, as will the rear housing. The firewall, cab interior, and exterior will be yellow. Then, I will add some touches of blue. The truck will be very bare, with no dash, as stripped down as possible, and as light as practical with standard parts. [that is to say, no expensive lightweight parts]

Larry Woodfin

|

| | | Posts: 2088 | Location: Longview TX | Registered: March 12, 2004 |    IP

IP

|

|

DRR S/Pro

| ^^^^^^ Larry, do you use a WP gasket between the block and engine plate or just silicone without gasket? |

| | |

DRR Pro

| Markemark, I have always used the Felpro blue gaskets. They are the common SBC gasket. I think that is better; it gives some extra compliance with the sealing.

Larry Woodfin

|

| | | Posts: 2088 | Location: Longview TX | Registered: March 12, 2004 |    IP

IP

|

|

DRR Pro

| Wooley, I use the engine hoist to lift one end at a time to set on the tables. At this point, it is ready to come off the tables. I began with a bare block and empty trans case to locate the crankshaft center line. The oil pan helped dictate the engine height and the engine is offset 1 1/2" to passenger side. [this aligns with the driveshaft tunnel which is also offset 1 1/2"] [this is OE placement] In the rear I used a pair of universal frame rails that are over length, allowing custom fitting. The bed has been on and off several times as I triple checked the tire, wheel, body clearance. With the wheels and tires in place, I worked the frame rails and rear housing to accommodate the wheel/tire placement. Everything is worked of rear wheel/tire location for rear frame and rear suspension. The ride height is based on front suspension/a arm position. The OE lower arm bump stops have about 1" clearance. This is a ride height about 2" lower the OE. Then the cab and OE frame section are set level and the rear rails are positioned as required. I will post a pic of the bed cut out. You will see that some of the rear frame is up in the bed. The truck will have a very slight rear rake [rear slightly higher than front] I do have a two-post lift, and the truck will be moved in it soon to complete some of the welding and ladder bar crossmember. More soon. Larry

Larry Woodfin

|

| | | Posts: 2088 | Location: Longview TX | Registered: March 12, 2004 |    IP

IP

|

|