Bracket Talk

Door car 4 link x link

April 10, 2020, 05:22 PM

CmichaelDoor car 4 link x link

What's everyone's take on a x link vs diagonal/ wishbone on a door car? Anyone try it? If so what's the pros and cons?

Wettstien Auto and Welding

Autometer

April 10, 2020, 06:37 PM

SCDIV1Vanishing Point Race cars made a sliding X-link for door cars and that was years ago.

They made it so it could be a bolt on arrangement to the existing bars if I recall right.

No longer in business though.

April 10, 2020, 08:16 PM

Stephen HughesI know this doesnt help but the car i’ve been building for a couple years now I built with an x link on the bottom bars. I figured if it doesnt work like I want it, a diagonal link and couple of 4-link bars is a pretty simple swap. I couldn’t come up with any reasons myself why it shouldn’t work on my application so thats the route I went. It’ll be next season or so before I know anything though.

The Pull-Out....for when you want to work smarter, not harder!!!

April 10, 2020, 09:22 PM

Mike RietowFloating X works, a guy I did a couple transmissions and an BBC engine, did an X locator on both his Ray Miller dragsters. Says they work great.

April 10, 2020, 10:28 PM

<DOTracer>We've built bolt in X links for a number of years now. In the past year or two we've gotten away from them for a couple of reasons. One is they are a real pain to adjust to center the rear. We find it becomes confusing for the customer to reinstall and keep the rear centered as it left the shop after the initial setup.

Also they weigh a little more than a conventional wishbone setup and as most of our customers being heads up cars, most everyone is very weight conscious.

Performance wise, no real difference than the wishbone but in some cases the X can be stronger depending on how the wishbone is made. Have seen alot of poorly constructed wishbones over the years.

April 10, 2020, 10:29 PM

<DOTracer>quote:

Originally posted by SCDIV1:

Vanishing Point Race cars made a sliding X-link for door cars and that was years ago.

They made it so it could be a bolt on arrangement to the existing bars if I recall right.

No longer in business though.

VP has been back in business for a couple of years now.

April 11, 2020, 08:38 AM

CmichaelDotracer, do you have any pictures?

Wettstien Auto and Welding

Autometer

April 11, 2020, 11:29 AM

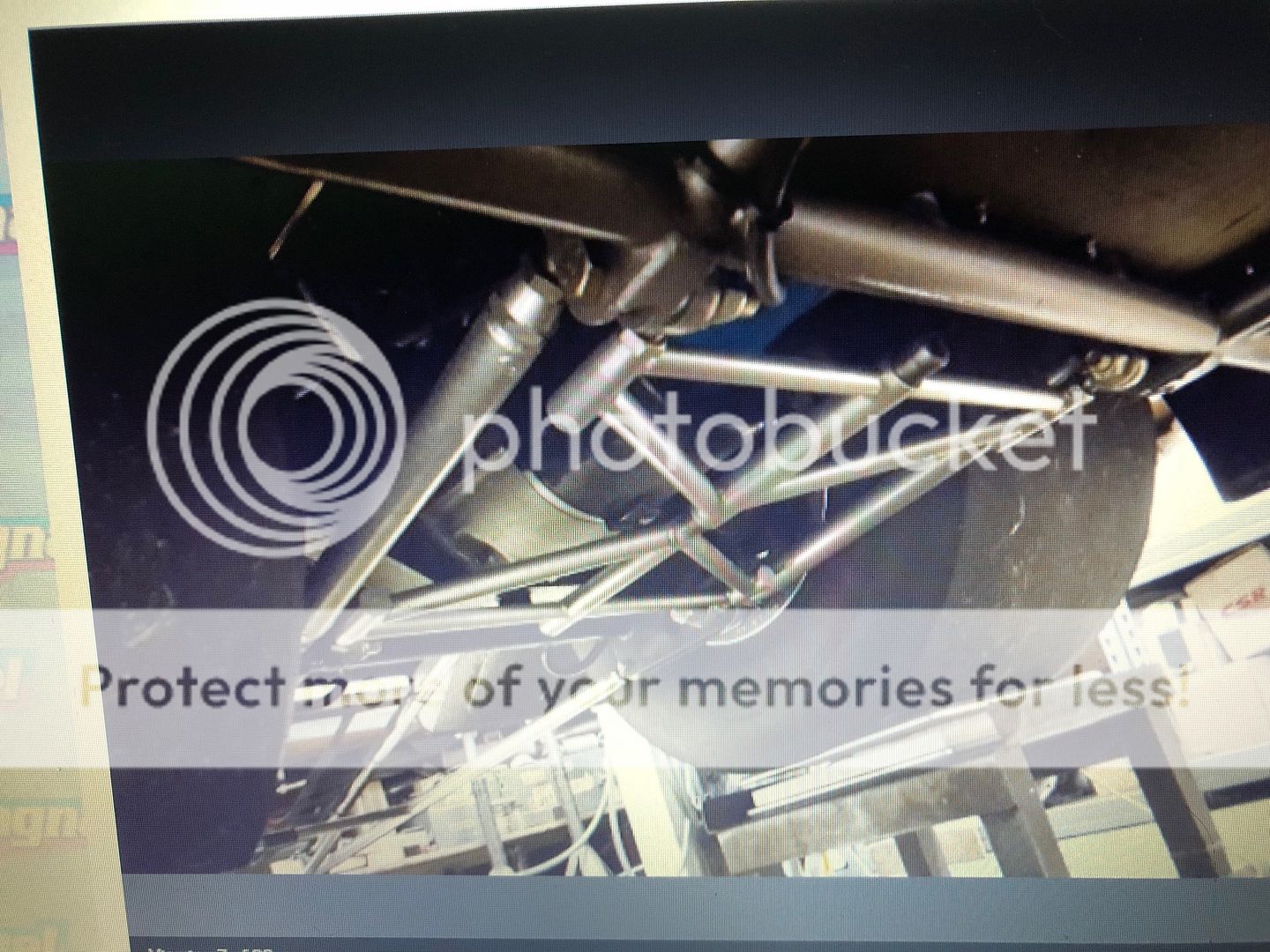

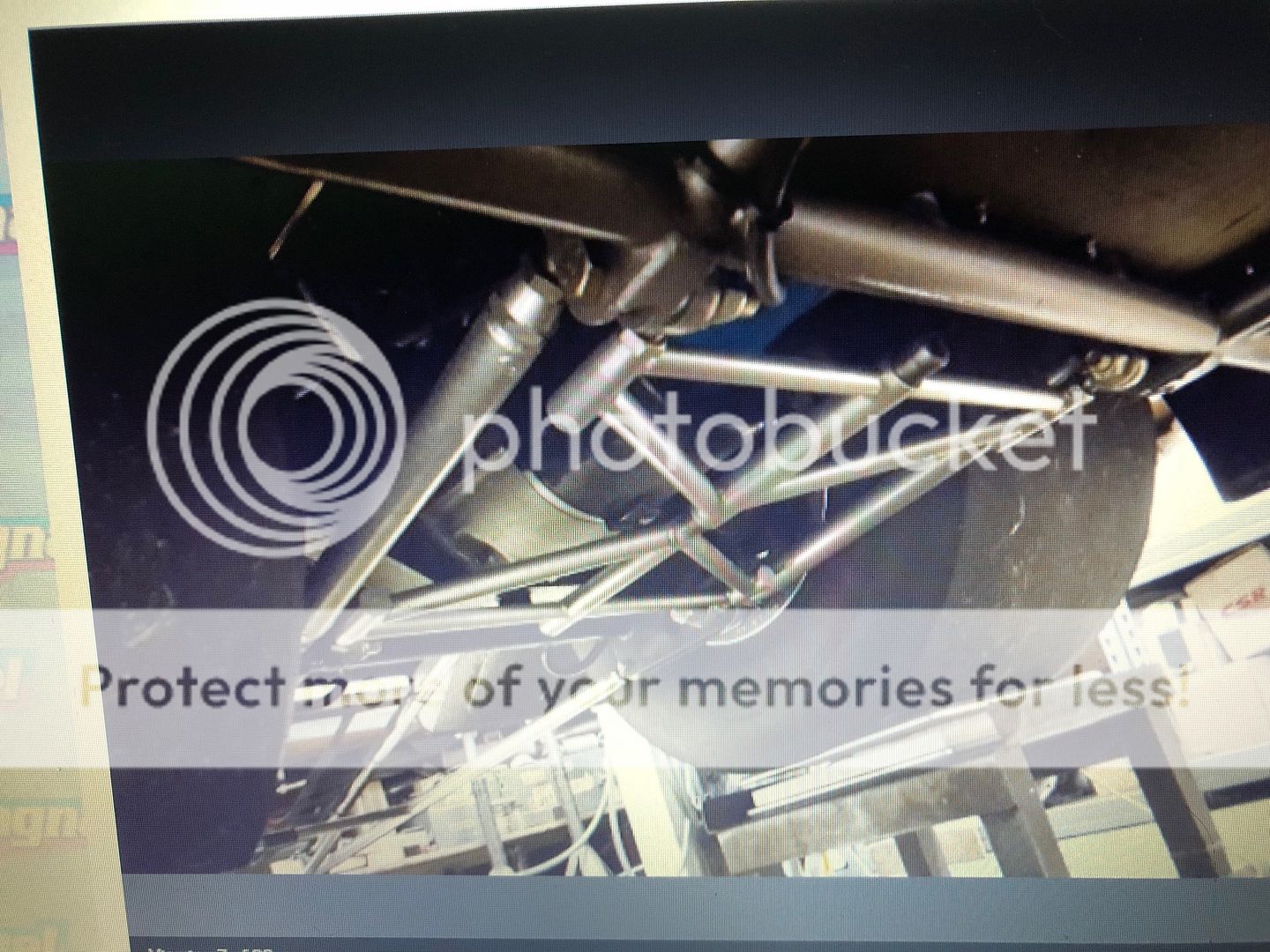

Mitch HDon’t know if I can pull this off from my phone, but one of my cars is a vanishing point chassis....

[IMG]https://hosting.photobucket.com/albums/j419/MAXGROWOUTDOORS/.highres/IMG_3781.jpg"> [/IMG]

April 11, 2020, 11:53 AM

SCDIV1One of my old friends has a Vanishing Point built Beretta and it has the sliding X

Another friend bought the same X and installed it in his car...

I replaced the wishbone on my Racetech dragster with a solid x-link

Bought it from Racetech and it was easy to install and adjust

I never liked the bottom mounted wishbones.....Kind of out of sight and out of mind and it gets a lot of dirt in the slding tube.

I replaced the tube and heim on mine a number of years ago...then decided to do the X

Can't really say it feels any different because the car was always very stable and solid at any speed.

There are some dragsters I've seen with the wishbone mounted on top. Its right in your view all the time and has grease fittings for the slide tube.

My old Vega had a wishbone mounted on the bottom and one heim at the housing end.....mounted with 1 bolt.....Dana Rear

Car felt a little loose one day and I found the bolt had loosened up......I spotted it in the lanes at Maple Grove

I tightened it in the lanes with an adjustable wrench I got from somebody...

Talk about an accident waiting to happen !!

My dragster had a much better design but still just one point of attachment.....

April 11, 2020, 12:04 PM

Mitch H

April 11, 2020, 01:33 PM

RacerVX54quote:

Originally posted by Mitch H:

Why tho seemss over complicated

"Just Shut Up and Race"

Brian Martin

Martin Racing

5.42 @127

April 13, 2020, 06:53 AM

willys1191Looks Identical to my Vanishing Point Sliding X My Chassis was built by Vanishing Point Race Cars in 98 and the sliding X was used on almost all their cars back then and possibly still using yet today

April 13, 2020, 07:18 AM

Mitch HThe one in my picture was built in 2012, so they were using them for a good while, and I think they still are.....

April 13, 2020, 07:51 AM

1320racerHave/had them all...diagonal on the firebird, X on the dragster and wishbone on the Chevelle. All work well with the 60 foots of the cars discussed in this forum.

April 13, 2020, 10:50 AM

TOP38For dragsters, an X link can help a bit if the car has no anti roll bar in it as this reduces the ability to let the rear/chassis roll. It also may help a bit for high HP combo's too, instead of adding preload to the anti roll deal, the X link provides the added stiffness.

But if everything is setup correctly they all work as Ed stated.

Ed Quay built his dragsters with the wishbone attached to the top of the rear housings, not sure why but he had his reasons.

April 13, 2020, 12:23 PM

David CoveyI read about a Pro Mod back in the early 2000's that was supposedly built in Australia using a swing arm suspension.

At the time it was thought to be the wave of the future because he consistently qualified well and went rounds.

I just can't remember who it was and the car..

I would think if it worked in a dragster it should work in a door car.

As to the sliding X I like it as well..

Anyone else heard of it?

Dave

"It is usually futile to try to talk facts and analysis to people who are enjoying a sense of moral superiority in their ignorance." -Thomas Sowell

April 13, 2020, 01:55 PM

Triple NickelNo need for a floating X link or slip on version. Make a jig, remove the two bottom bars, square the bars in jig, and weld an X in between them. Ran 8.40's for years in a door car done just like this, built it in 2002, car is still around today with the same welded X link running 8.90 range. The slip on deal is cool if you don't have the ability to weld and or not able to build a very simple jig to keep the bars square and level while you weld them together, you can order from a chassis builder and install yourself.

Only downside for welding the X in the bars i can come up with is you gotta remove both front bolts or both back bolts and drop the bottom X link like a swing arm if you want to change the wheelbase. I only set mine up once so it was a minor pain in the butt for that one initial setup but i never removed it after it was installed.

I preferred the welded X over a diagonal link and or wishbone configuration, much less hassle once the initial chassis setup is complete and rear end is square in the car. My Miller 4 link Dragster has the slip on "K" link, its a pain in the butt to get the powder coated bottom 4 link bars installed into it cause the slip fit is so tight. The X or K link idea also eliminates some body roll associated with diagonal links and wishbones. Looking at the floating X pictured in one of the posts above its no better than a wishbone as far as anti roll properties.

April 14, 2020, 10:51 AM

David Coveyquote:

Originally posted by Triple Nickel:

No need for a floating X link or slip on version. Make a jig, remove the two bottom bars, square the bars in jig, and weld an X in between them. Ran 8.40's for years in a door car done just like this, built it in 2002, car is still around today with the same welded X link running 8.90 range. The slip on deal is cool if you don't have the ability to weld and or not able to build a very simple jig to keep the bars square and level while you weld them together, you can order from a chassis builder and install yourself.

Only downside for welding the X in the bars i can come up with is you gotta remove both front bolts or both back bolts and drop the bottom X link like a swing arm if you want to change the wheelbase. I only set mine up once so it was a minor pain in the butt for that one initial setup but i never removed it after it was installed.

I preferred the welded X over a diagonal link and or wishbone configuration, much less hassle once the initial chassis setup is complete and rear end is square in the car. My Miller 4 link Dragster has the slip on "K" link, its a pain in the butt to get the powder coated bottom 4 link bars installed into it cause the slip fit is so tight. The X or K link idea also eliminates some body roll associated with diagonal links and wishbones. Looking at the floating X pictured in one of the posts above its no better than a wishbone as far as anti roll properties.

"It is usually futile to try to talk facts and analysis to people who are enjoying a sense of moral superiority in their ignorance." -Thomas Sowell

April 14, 2020, 10:57 AM

Triple NickelJason Wood at Wizzard Racecars tried the swing arm deal on his 59 cadillac hearse pro mod about 10 years ago, it didn't work out and he swapped it to a conventional 4 link a few years later. Not sure of all the reasons swapped back to 4 link but the swing arm just didn't pan out for him.

April 15, 2020, 08:51 PM

C HodgeI have my lower tied together in my nova. Lower bars are 1 1/4 with 4- 1 3/8 X2” slid over it with a hoop and 2 down bars like a swing arm dragster welded to them and one bar bent to clear the center across at the rear. The 4-link bars still adjust like any 4-link bars will. This lets you pull the center without taking the lower link out. If you just going to weld an X in it will bend unless you run a anti roll bar. In front and behind each 2” piece is a 1/4 “ long 1 3/8 so the link cant slide. You still have to take the lower out if side to side needs adjusted but not if your just moving wheelbase. I don’t run an anti roll and don’t need one with this setup