|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bracket Talk

Bracket Talk  Bracket Talk Forum

Bracket Talk Forum  Tech Talk - by Abruzzi

Tech Talk - by Abruzzi  Chevy LS engine build up for the Colorado

Chevy LS engine build up for the ColoradoGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| DRR Pro |

First the back ground and personal comments. I am now working on my 75th birthday, working hard on it! My first SBC build up was around 1963 as I stepped up from 235 six cylinder stove bolts and 1951 flat head Plymouth. It was a quick leap and since the 63 date I have built and successfully raced countless SBC's. I credit my Son, Jeff Woodfin as the key to my first LS engine. Were it not for his encouragement, the Colorao would be equipped with a fist gen SBC. Chevy brought the LS engine to the market in 1997, some 24 years ago. Yet, hard core racers have been slow to make the change over. [my self included] My research shows the LS engine to be popular with the bolt on, street performance folks, but a purpous built, bracket race package is rarely seen. So, with respect and reverence to the past, and with years of common sense of what works in any engine, here we go. Please stay tuned and check back ofter. Larry Woodfin | ||

|

| DRR Pro |

Bucky, tell about your oil pressure problem and what you did to correct it. Larry Woodfin | |||

|

| DRR Trophy |

Following. I'd like to also increase my LS knowledge. I have a candidate 4th Gen Camaro that I would like to either do an standard SBC swap, or LS. I would really like to put in LS, due to distributor and carb clearance, but I am also concerned with wiring harnesses, ECM's, which generations of LS. Basically I don't know what I need or don't need. What I do know is that I need to decide before I order a K Member. It's important to me that it's not a hack job. | |||

|

| DRR Trophy |

Count me in on following this as well. Other than the stock oiling system short comings the LS has checked all the other boxes. What I have concluded, the dry sump setup is the only way to eliminate the factory wet sump short comings. When your oil sump is as far from the oil pump as possible and the o-ring seal is the lifeline connecting to the oil pump, failure is imminent in high demand applications. Look forward to learning what other options exist... | |||

|

| DRR S/Pro |

Larry, Are you planning to use MSD 6014 LS Ignition controller for CNP configuration? | |||

|

| DRR Trophy |

I am very excited to see what you do with your build Larry! This past season was our first endeavor into the LS world as we traded my dragster for a backhalf rolling 71 camaro. We ended up wanting to go a conservative route so we bought a CT525 crate engine as it came with pretty much everything we needed to bolt on a carburetor, hook up an MSD 6014 ignition box and then a few minor parts here and there (converter, headers and engine mounts mainly) and it has been almost flawless this entire season. On alcohol the car runs 6.40's at 105 mph, 2800lbs on the starting line, and is easily one of the most consistent and reliable race cars we've ever put together. No plans in the near future to "build" the engine as it has forged pistons from the factory (part of the CT525 deal) and should run quite a few seasons before needing freshened. Best part is, if you keep it hydraulic roller there's little to no maintenance required to keeping the thing running throughout the year minus an oil change here or there, mainly cause you feel guilty about not doing anything with it! Nick Craig 1971 Camaro Split Bumper 376ci LS3 | |||

|

| DRR Pro |

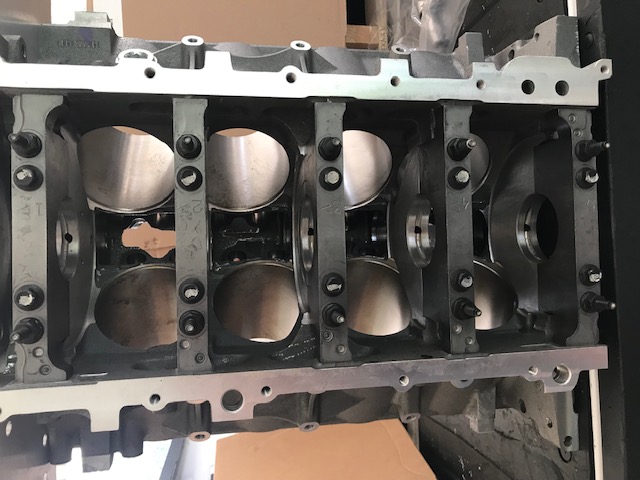

The plan is to use a Methanol carb and the Dayton Sensors controller which will have 8 ignition coils. The new block for GM arrived today Larry Woodfin | |||

|

| DRR Pro |

new block Larry Woodfin  | |||

|

| DRR Pro |

block Larry Woodfin  | |||

|

DRR Top Comp |

The LSXR 454R Chevy made for a while put out advertised 750? Hp and they say would dyno at over 800. And it was not that bad. Last ones I saw was around $13,000? IIRC brand new. List price of $17,000. If you was going to do an LS type platform I would look into building something very similar to the LSXR 454. https://postimg.cc/gallery/np3zpruo/ "Dunning-Kruger Effect" -a type of Cognitive bias where people with little expertise or ability assume they have superior expertise or ability. This overestimation occurs as a result of the fact that they do not have enough knowledge to know they don't have enough knowledge. Before you argue with someone ask yourself, "Is this person mentally mature enough to grasp the concept of a different perspective?" If not there is no point to argue. 4X NE2 CHAMPION. 2020 TDRA NE2 Champion | |||

|

| DRR Sportsman |

If you’re cam bearings are too tight you wouldn’t know it till it spun all the bearings. Both oil pressure ports are before the cam bearings. I made over 100 psi all the way to 9000 rpm a couple weeks ago. All stock oiling system at 1000 hp. I’m sure I’ll have problems at some point, but I really wonder how many “problems” are the wrong oring and too much pickup clearance. I forgot, I did add the secondary clamp on the pickup to pump connection. Maybe that’s the magic. I made 70 psi at 7k rpms on an engine that, upon disassembly, had approximately 90% of the bearing material in the pan. That motor had every excuse to crap the bearings out of it, just couldn’t believe it still had that much oil pressure. The small filters make me nervous. I started to run the truck filter but keep catching it on the trailer bc it’s 1/4” below the pan I’d LOVE to see somebody build a stock block/crank 5.3 with a Tbs 250 (baby) blower for a bracket car. I think it would be the best hp/$ and super simpleThis message has been edited. Last edited by: BJs Wild Ride, | |||

|

| DRR Sportsman |

If it's not already done, drill and use the second bolt hole for the oil pump pickup, they're bad about either falling out or tilting slightly and allowing aeration. Also be very careful inserting the pick-up O-ring, they're problematic if not done just right. Organized people are just too lazy to look for their $h!t. | |||

|

| DRR Trophy |

Bucky, does your oil pan have the stock location oil passage ways? The ports in question are found at the rear driver side rail on the pan. You can block those ports off and dead head the oil pressure at that location. | |||

|

| DRR Trophy |

I modified a cooler line adapter to use for priming new builds, machined off the factory lines then drilled and tapped 3/8"NPT holes to use AN adapters fittings and pipe plugs. The pressure could be monitored at the front passage way. The front port would be direct pressure from the pump, I believe the rear port would measure the pressure at the return side of the oil circuit?? | |||

|

| DRR Sportsman |

Sorry Larry. But I guess you could look at it like the old yellow bullet guys that drove the bus around to keep the thread at the top. Bucky, what exactly is it doing? I’ve assembled and fired a handful of Ls motors at this point and never had the “common” problem of not getting oil pressure right away. Until last time. I cranked the battery dead. Zero. Finally just fired it and it took a fairly uncomfortable amount of time to pop the gauge up. Its supposedly pretty common. I have used a pre-primer exactly once but the pump I was using died. Crank it up with any of the galley plugs out and you’ll know if you have flow. If not, cobble a primer that will at least back feed the pump. If you’re not sure whether the oring is tight enough, then it’s probably not tight enough. If it looks right, it’s probably too small. | |||

|

| DRR Sportsman |

I’m not looking at it right now but pretty sure the Oil goes through the adapter to the motor. Pump-filter-through adapter-across barbell-up to stock pressure port-through cam and lifters-down to crank. That’s my recollection anyway. | |||

|

| DRR Top Comp |

LS rule of thumb - You're gonna need a 10,000 rpm tachometer in the car with 750 hp n/a. At 3200 lbs, you won't out run The Ripper conventional sbc, n/a. If all drag racing were 1/4 mile or 1/2 mile, the LS would hold all the sbc records already. That's a big if. TORQUE = HP x 5252 ÷ RPM | |||

|

| DRR Trophy |

I've seen more than enough reputable engine builders make 700-750 with nothing too exotic in the LS world and keep it hydraulic and under 7500rpm. https://www.shafiroff.com/chev...drag-race-engine.php http://www.siebertperformance....bracket-441-ls-750hp With that said, with what Larry is trying to do with building a bracket engine, it's almost a no brainer starting with a new build entirely to go the LS route to easily make 550-600 to even 650hp with little to no effort and have it as reliable as a 150,000+ mile truck engine. Nick Craig 1971 Camaro Split Bumper 376ci LS3 | |||

|

| DRR Top Comp |

I stand corrected. I meant to say 750 HP at the local drag strip, n/a. | |||

|

| DRR S/Pro |

Sportsman racers are traditionally wet sump. It's familiar and inexpensive. But as long as they have been making LS Z06's, ZR-1's and manual trans Grand Sports, there are bound to be dry sump systems available at reasonable prices. Not all that knowledgeable but the dry sump LS3's have a forged crank with a longer snout. Illegitimi non carborundum | |||

|

| Powered by Social Strata | Page 1 2 |

| Please Wait. Your request is being processed... |

|

Bracket Talk

Bracket Talk  Bracket Talk Forum

Bracket Talk Forum  Tech Talk - by Abruzzi

Tech Talk - by Abruzzi  Chevy LS engine build up for the Colorado

Chevy LS engine build up for the Colorado

|

|

|

|